|

|||||||||||

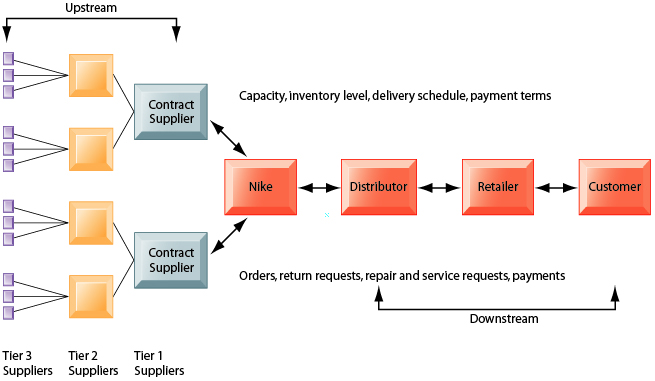

Supply Chain Management Systems Supply chain management refers to the coordination of activities and involved in making and moving a product. The supply chain is the network of businesses and business processes involved the creation and selling of a product, from suppliers that procure raw materials through retail outlets and customers. The upstream portion of the supply chain includes the organization's suppliers and the processes for managing relationships with them. The downstream portion consists of the organizations and processes for distributing and delivering products to the final customers. The manufacturer also has internal supply chain processes for transforming the materials and services furnished by suppliers into finished goods and for managing materials and inventory.

Inefficiencies in the supply chain, such as parts shortages, underutilized plant capacity, excessive inventory, or runaway transportation costs, are caused by inaccurate or untimely information and can waste as much as 25% of operating costs. Uncertainties also arise because many events cannot be foreseen—product demand, late shipments from suppliers, defective parts or raw material, or production process breakdowns. More accurate information from supply chain management systems reduces uncertainty and the impact of the bullwhip effect, in which information about the demand for a product gets distorted as it passes from one entity to the next across the supply chain. With perfect information about demand and production, a firm can implement an effective just-in-time strategy, delivering goods in the right amount and as they are needed.

Supply chain software can be classified as either:

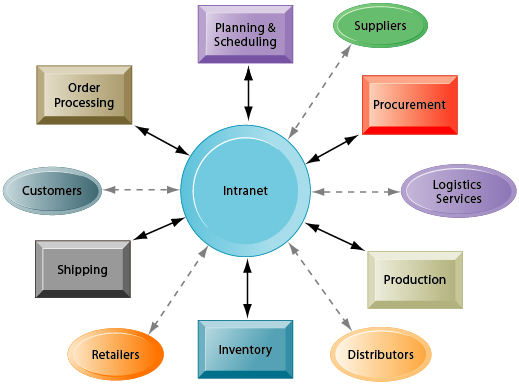

Before the Internet, supply chain coordination was hampered by the difficulties of making information flow smoothly among disparate internal supply chain systems. Today, using intranets and extranets, all members of the supply chain can instantly communicate with each other, using up-to-date information to adjust purchasing, logistics, manufacturing, packaging, and schedules. The Internet provides a standard set of tools that are used by companies all over the world to coordinate global supply chains that include participants from many countries

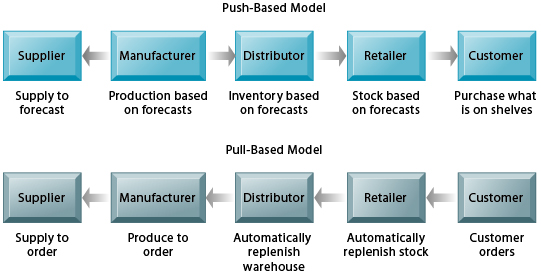

Earlier supply chain management systems were driven by a push-based model (also known as build-to-stock) in which production master schedules are based on forecasts or best guesses of demand for products, and products are "pushed" to customers. With Web-based tools, supply chain management follows a pull-based model (or demand-driven model or build-to-order), in which actual customer orders or purchases trigger events in the supply chain.

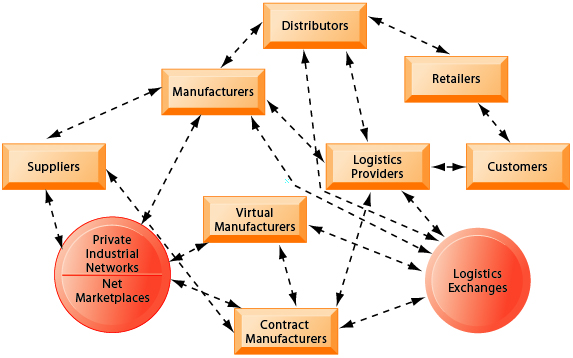

Internet technology also makes it possible to move from sequential supply chains, where information and materials flow sequentially from company to company, to concurrent supply chains, where information flows in many directions simultaneously among members of a supply chain network. Ultimately, the Internet could create a "digital logistics nervous system" throughout the supply chain to permit simultaneous, multidirectional communication of information about participants' inventories, orders, and capacities.

The business value of supply chain management systems includes:

|