[previous] [next] [contents]

![]() Implementation

of the 1149.4 demo "component"

Implementation

of the 1149.4 demo "component"

The

implementation technology should meet three main objectives: be widely

available, be flexible (to enable modifications / upgrades, if required)

and be pedagogical (i.e. make explicit the operation of the internal test

circuitry). The best alternative, requiring a relatively small number of

IC packages, consists of implementing the digital test infrastructure and

core logic in an EPM7128 Altera PLD (2.500 usable gates, 128 macrocells,

84-pin PLCC), and using discrete components to implement all the remaining

blocks (ADG452 analog switches, LM311 comparators, TL081 operational

amplifier).

Figure

1: Top-level

representation of the digital test infrastructure and core (logic

inverter).

The digital test infrastructure and core logic (simply a logic inverter) was implemented by Dr. Gustavo Alves of ISEP and is illustrated in figure 1, which lists all input / output signals that interface the remaining (analog) blocks. This block was designed using the Max+plus II Baseline software, where a schematic representation was selected for the upper hierarchical levels – the top level is shown in figure 2 -, and a hardware description language (AHDL) representation for the lower levels.

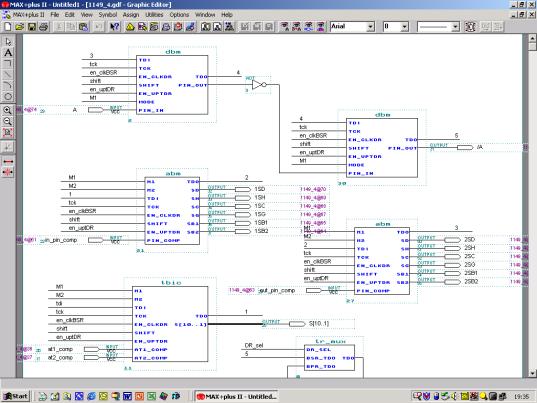

Figure

2: Max+plus II -

Top-level representation of the digital test infrastructure and logic

inverter.

Each block

represented in figure 2 will either be described directly in AHDL, if no

intermediate hierarchical levels are present, or by a further breakdown of

blocks, represented in schematic diagram form, which are then described in

AHDL. As an example, figure 3 shows the representation of each ABM, which

comprises a (4-bit) control register and a decoder (generating the control

signals for the analog switches).

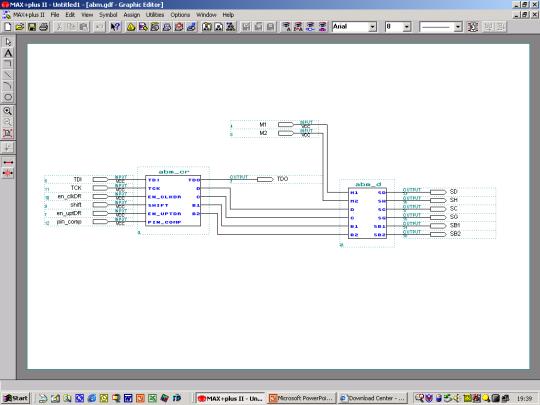

Figure

3: Schematic

representation of the digital circuitry comprised in each ABM.

Each block

represented in figure 3 is then described in AHDL. This hardware

description language provides a very straightforward representation of the

required logic functions, as may be seen by analyzing the section that

refers to the ABM control structure, shown in figure 4.

Figure

4: AHDL representation of the ABM control structure.

The ABM

switching decoder provides another good example of the readability of AHDL.

Figure 5 shows that this combinational circuit was specified in the form

of a table, where each line represents the input / output relationship

required for each switching pattern.

Figure

5: AHDL representation of

the ABM switching structure decoder.

The

implementation of the switching structures of the TBIC and ABMs is based

on discrete components, as was previously referred. Figure 6 shows the

schematic diagram representation of the TBIC switching structure, which

uses ADG452 analog switches and LM311 open-collector output comparators.

Figure

6: Implementation of the

TBIC switching structure.

The switching

structure of the ABMs uses the same components and is represented in

figure 7, together with the internal core circuitry (the voltage

follower).

Figure

7: Implementation of the

ABMs switching structure.

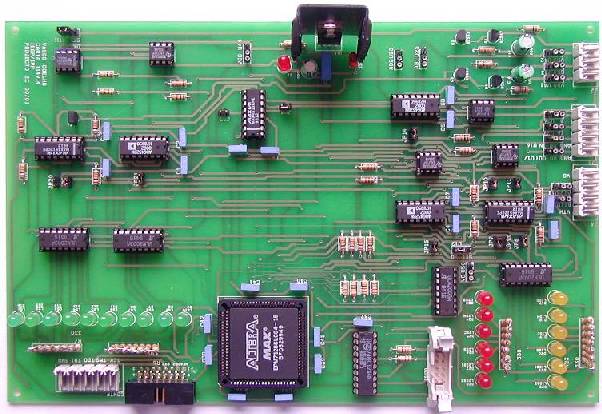

The whole

1149.4 “component” was assembled in a printed circuit board that is

shown in figure 8.

Figure

8: The 1149.4 demo

“component”.